Why Prefab ADUs Cost Less Than Traditional Builds

Accessory Dwelling Units, known as ADUs, serve as effective solutions for homeowners seeking to add living space and boost property value. Prefabricated ADUs present a quicker, more economical option for installing a backyard unit while maintaining high standards of comfort and durability. Grasping the reasons behind their lower costs empowers you to decide wisely for your expansion project.

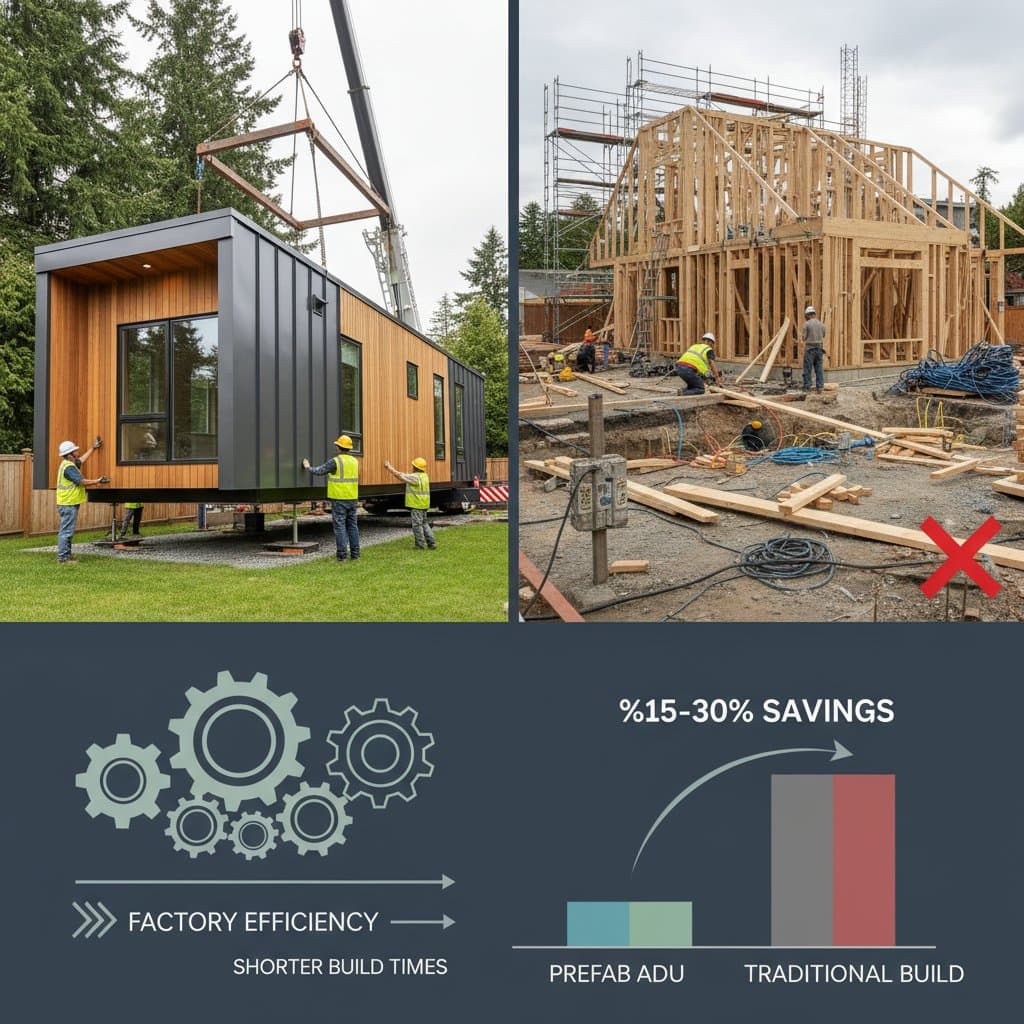

This overview details the financial benefits of prefab ADUs, including enhanced efficiency, decreased labor expenses, and reliable schedules. It further covers customization possibilities, expense analyses, and scenarios requiring expert assistance.

Understanding Prefab ADUs

Prefab ADUs consist of modules constructed within a regulated factory setting, followed by transportation and on-site assembly. This approach contrasts with traditional methods, where all work occurs directly at the location. Factory production enables precise cost control and shields against interruptions from weather or material shortages.

A standard prefab ADU arrives with integrated plumbing, electrical systems, and interior finishes. Upon delivery, crews connect it to site utilities and anchor it to a prepped foundation. Such an organized process cuts installation duration and labor demands considerably.

Shorter Construction Timelines

Prefab ADUs progress from initial order to occupancy far more rapidly than on-site constructions. Parallel execution of factory work and site readiness compresses the total project duration. In contrast, traditional builds sequence each phase sequentially, prolonging timelines and increasing labor commitments.

Accelerated schedules lower interest on loans, minimize household interruptions, and hasten access to rental revenue. Consider these benchmarks:

- Prefab ADU: 3 to 5 months from design approval to occupancy

- Traditional ADU: 6 to 12 months, varying by site challenges

These reductions in time translate to direct savings on workforce and oversight expenses, contributing to the overall affordability.

Reduced Labor Costs

Factory assembly demands fewer on-site workers, as skilled teams complete most structural and systems work indoors. Traditional projects rely heavily on field labor, which fluctuates with weather and availability, driving up hourly rates and overtime.

Prefab methods standardize tasks, allowing crews to specialize and operate efficiently. Homeowners benefit from predictable labor budgets, often 20-25% below those of conventional builds. To maximize this, select manufacturers with established installation networks that streamline coordination.

Bulk Purchasing and Material Efficiency

Prefab producers secure materials in volume from direct sources, securing discounts on essentials like timber, electrical components, insulation, and hardware. This scale yields notable economies that traditional small-scale purchases cannot match.

Controlled factory conditions further optimize resource use, with scraps from one assembly repurposed for others. Site-based construction generates excess waste, incurring additional hauling and disposal fees. Key savings include:

- 10 to 15% lower material expenses for prefab units

- Reduced environmental impact through minimized landfill contributions

These efficiencies ensure competitive pricing without sacrificing material quality.

Simplified Permitting and Inspection

Prefab ADUs benefit from pre-certification under state or regional factory standards, where inspections occur during production. Site reviews then concentrate on foundations, utility integrations, and final assemblies, streamlining local approvals.

This front-loaded compliance accelerates permitting and curtails fees associated with repeated visits. Traditional builds often face extended reviews due to progressive on-site changes. Engage your local building department early to confirm prefab eligibility and prepare documentation for swift processing.

DIY vs Professional Installation

Homeowners may handle certain preparatory or finishing elements to control expenses. However, core installation phases demand certified expertise to uphold safety and regulations.

Suitable for DIY:

- Site clearing and vegetation removal

- Interior painting and decor selection

- Non-load-bearing additions like flooring or shelving

Require Professionals:

- Foundation excavation and pouring

- Electrical, plumbing, and drainage hookups

- Crane operations for module positioning

- Adherence to building codes and final inspections

Partner with licensed contractors experienced in prefab setups. Manufacturers frequently recommend vetted installers who guarantee seamless integration and preserve product warranties.

Maintenance and Durability

Every prefab ADU phase incorporates rigorous quality assessments, guaranteeing robust construction and resilience to elements. Indoor material storage prevents pre-assembly degradation from humidity or pests.

Post-installation care mirrors that of compact residences: periodic roof evaluations, sealant renewals, and climate control tune-ups. Leading providers extend warranties on frameworks and surfaces, supporting sustained performance. Schedule annual professional reviews to extend the unit's lifespan beyond 50 years.

When to Hire a Professional

Engage experts for any elements involving load-bearing structures, power systems, or water lines. Specialists in ADUs assist with:

- Terrain assessment and soil grading

- Custom foundation engineering

- Utility routing and underground lines

- Zoning compliance and permit applications

- Logistics for transport and securing

Vet candidates by examining portfolios of completed ADUs, confirming credentials, and securing client testimonials. Inquire about coverage terms, regulatory guidance, and update protocols to foster a collaborative process.

Common Questions About Prefab ADU Costs

Do prefab ADUs differ in appearance from site-built ones?

Modern designs feature diverse facades and materials that blend seamlessly with primary residences or community aesthetics.

Is customization available?

Absolutely. Providers allow selections in floor plans, exteriors like cladding or tiles, and internals such as palettes, preserving production advantages.

Do they comply with building standards?

Yes. Factory units adhere to identical codes as traditional homes, with inspections at assembly milestones.

Are permits necessary?

Indeed. Site-specific approvals for bases and services apply, but pre-vetted designs expedite the procedure.

What is their expected lifespan?

Proper upkeep enables prefab ADUs to endure as long as conventional dwellings, typically 40-60 years or longer.

Advancing Your ADU Project

Prefab ADUs deliver economical expansion and income potential through disciplined manufacturing, lean staffing, and fixed costs. They stand as viable substitutes for labor-intensive traditional methods.

Define your objectives, such as accommodating relatives, hosting visitors, or leasing space. Review municipal regulations next, then consult reputable prefab specialists to evaluate configurations and estimates.

With thorough preparation and skilled collaboration, secure a durable ADU that aligns with finances, elevates your estate, and yields enduring utility.