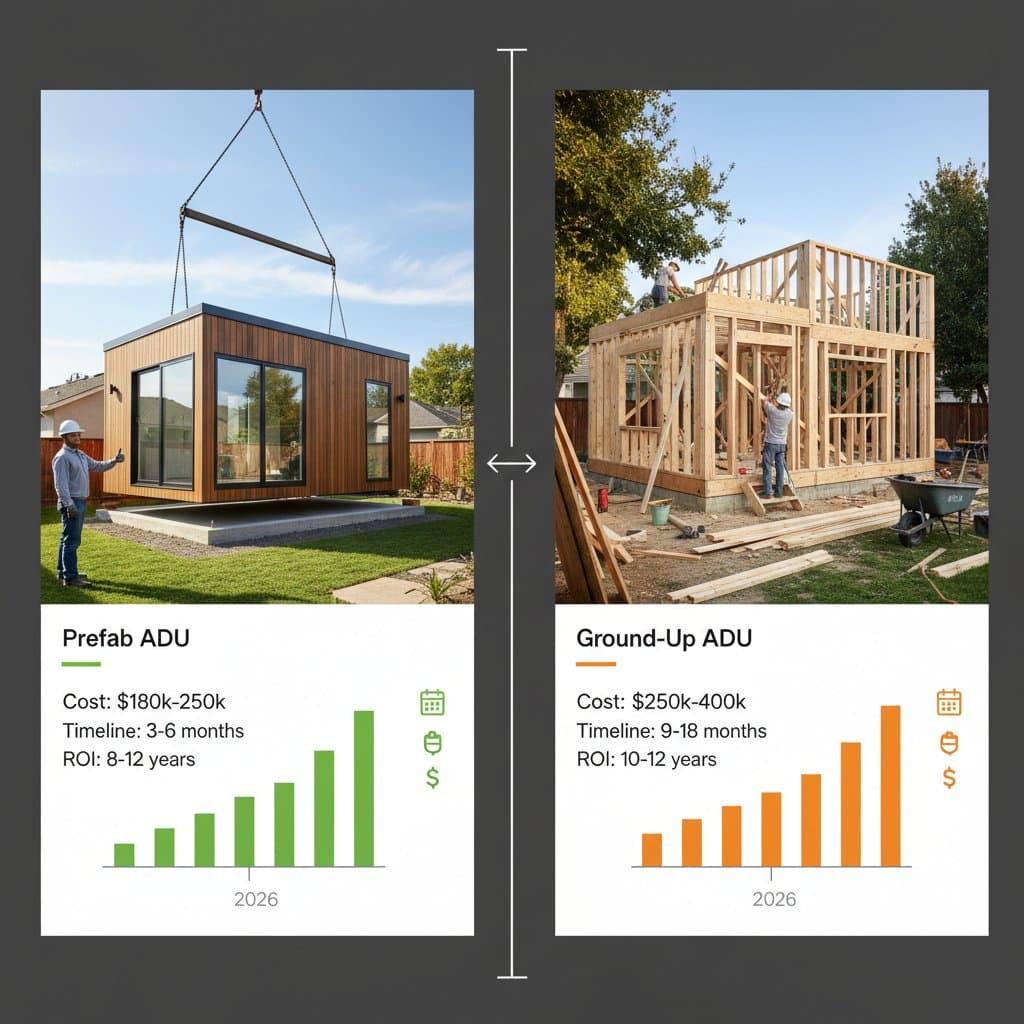

Prefab ADU Costs and Timelines: What to Expect in 2026

Quick Overview

A prefab accessory dwelling unit functions as a compact, factory-assembled structure placed in a backyard or on a property. Such units expand living areas, generate rental revenue, or accommodate family needs. Expect a timeline of three to six months from initial order to occupancy, with total expenses spanning $70,000 to $200,000 based on dimensions, interior quality, and site requirements. The project demands moderate effort and carries manageable risks when permits and installation protocols receive strict adherence.

Essential Preparations

Verify local zoning regulations to determine ADU eligibility on your property. Building departments typically mandate a primary permit, alongside approvals for utility integrations in certain jurisdictions. Restrictions may apply to dimensions, elevation, or resident capacity. Secure confirmation of these elements prior to committing to contracts or acquiring units.

Safety Advisory:

Avoid excavation, trenching, or utility linkages without prior assessment of subsurface elements. Contact the regional utility locator service before any ground disturbance. Engage certified experts for electrical, gas, or sewage systems.

Project Complexity: Moderate, involving oversight of various phases and specialist teams.

Timeline Projection: Three to six months spanning initial planning through to habitation.

Required Equipment and Supplies

Assemble the following:

- A measuring tape extending at least 100 feet

- A level instrument and stakes for precise site demarcation

- Shovels and rakes suitable for basic soil adjustment

- Safety equipment including gloves, helmets, and protective eyewear

- Contractor-provided machinery for foundational tasks

- Concrete mix for slab or pier bases

- Trenching components such as conduits, water piping, and drainage lines

- A prefab ADU assembly sourced from a certified producer

Detailed Installation Guide

1. Select the Optimal Site

Identify a flat terrain segment that complies with mandated distances from boundaries. Assess pathways for transport vehicles and potential crane positioning.

Verification Step: Confirm alignment with municipal zoning and utility avoidance guidelines.

2. Secure Necessary Permits

Present detailed prefab ADU schematics to the relevant authority, encompassing foundation designs, utility schematics, and terrain configurations.

Verification Step: Proceed with material procurement only upon receipt of formal authorization.

3. Conduct Site Preparation

Clear foliage, level the ground, and outline the foundation perimeter. Ensure adequate runoff directs water clear of the designated area.

Verification Step: Achieve a stable, compacted subsurface to minimize future displacement.

4. Construct the Foundation

Prefab ADUs commonly employ concrete slabs or pier systems. Adhere to producer directives regarding depth, reinforcement, and placement.

Caution: Proper curing and alignment prove essential in concrete applications; retain qualified contractors absent prior expertise.

Verification Step: Gauge opposing corners to validate squareness.

5. Facilitate Utility Integrations

Organize excavation and placement of conduits for electricity, water supply, and waste removal.

Electrical Precaution: Licensed electricians must oversee all wiring connections.

Verification Step: Examine excavations prior to refilling to affirm appropriate depths and intervals.

6. Arrange Delivery and Positioning

Units arrive either segmented or fully assembled. Maintain unobstructed routes for haulage equipment.

Elevation Hazard: Maintain distance from lifting operations; designate trained operators for alignment.

Verification Step: Ensure secure foundation seating and fastening of all restraints.

7. Finalize Utility Links and Interior Work

Post-positioning, integrate services and weatherproof accesses. Complete any on-site interior elements like flooring or moldings if factory provisions fall short.

Verification Step: Test operational integrity of systems before enclosing structures.

8. Obtain Clearance Inspection

Schedule a concluding review with the building authority.

Verification Step: Acquire the occupancy certification prior to utilization or leasing.

Post-Installation Cleanup

Evacuate debris, wrappings, and refuse from the area. Direct recyclable aggregates like concrete or metals to designated centers. Handle treated lumber and insulators per jurisdictional protocols. Restore vegetation in altered zones and sanitize the premises.

Inspection Protocols and Issue Resolution

Frequent challenges encompass foundation shifts, door misalignments, or inadequate drainage.

- For tilting structures or binding entries, reassess base evenness and adjust surrounding earth.

- Address gutter backups by lengthening discharge pipes or installing deflection guards.

- Resolve circuit interruptions through professional electrician evaluation of capacity and connections.

Conduct examinations of roofing, exteriors, and joints following severe weather events. Prompt interventions avert extensive moisture-related deterioration.

Long-Term Care and Durability

Properly executed prefab ADUs endure for multiple decades under regular upkeep.

- Clean exterior panels yearly using gentle soap solutions.

- Refresh paint or sealants on timber elements every five years.

- Annually survey roofing materials for deterioration or detachment.

- Perform yearly draining and rinsing of heating units.

Scenarios Requiring Expert Intervention

Consult licensed builders or contractors for:

- Wiring or fuel line setups

- Foundational adjustments or load-bearing fixes

- Advanced moisture barriers or terrain modifications

Hourly fees for such services generally fall between $50 and $100. Confirm credentials, coverage, and endorsements before engagement.

Strategies for Optimal Outcomes

- Initiate prefab orders solely post-permit validation to circumvent warehousing charges.

- Evaluate heavy-lift access at the outset for constrained or enclosed sites.

- Allocate a 10 percent reserve in your budget for unforeseen terrain, service, or review expenses.

- Maintain photographic records of proceedings for documentation in sales or claims contexts.

Thorough foresight and meticulous oversight transform a prefab ADU into a durable, versatile asset, bypassing the protracted phases of conventional builds. Adhering to these protocols safeguards expenditures, schedules, and compliance while delivering enduring value.